Welcome to a new InTheMail, the series that will touch both your passion for electronics and your bank account at the same time.

Voltlog #260 – How do you test usb to serial converters? (CP2103 vs CH340E vs FT232RL)

Welcome to a new Voltlog, today we’re comparing a few different serial to usb adapters and the discussion started ever since I showed the CH340E breakout board I designed in voltlog #249. People wanted to know if this CH340E affordable chip would perform similar to the well known FTDI or Silicon labs chips, and I’m thinking at high throughput and reliability here, the kind of application where you are sending lots of data, fast and you need it to be transferred reliably.

So today I’m going to compare the CH340E with a CP2103, and the FT232RL. I wasn’t sure what measurements to take and how to test these but I devised 2 testing methods.

Voltlog #259 – InTheMail

Welcome to a new InTheMail, the series that will touch both your passion for electronics and your bank account at the same time. We’re going to start with this small white box, which looks very uninteresting from the outside but contains something really nice, it’s a machined aluminium heatsink, designed specifically for the raspberry pi 4 and inside the box you get the two halves of the heatsink plus some mounting screws and silicone thermal pads.

There is a decent amount of aluminium in this heatsink, and we can see it has these rectangular raised islands for contact with the main chips on the board, so this is where the silicone pads will go. This is a completely passive heatsink and that’s what I was looking for but if you want more cooling power these are also actively cooled heatsink. feel like I should test this in a separate video to see how efficient it is when compared to a no heatsink solution which we already know doesn’t work well with the raspberry pi as it gets pretty hot. So we’ll leave this for a future video.

Voltlog #258 – Cheaper Isopropyl Alcohol Wipes For PCB and Stencil Cleaning

Welcome to a new Voltlog, today we’ll have a little chat on IPA cleaning wipes. Professional PCB wipes soaked in IPA are pretty expensive and hard to get but can we substitute those with something cheaper that works just as nice for cleaning the flux residue from PCBs?

Voltlog #257 – ESP32 PIR Motion Sensor With Deep Sleep & MQTT (revB part2)

In this video I’m gonna show the second revision of my esp32, battery powered PIR motion sensor. This second revision contains some optimizations to improve deep sleep power consumption as well as to fix some of the errors I had the first revision of the pcb.

Voltlog #256 – Best BST-863 Hot Air Rework Station (Alternative to Quick 861DW)

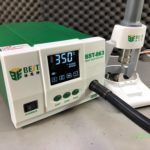

Inside the box of the BST-863 we have the station, a really nice and heavy stand for the tool piece, a total of 3 nozzles, a grounding strap and a power cord. The first thing I notice is the hose which pretty thick, certainly thicker than what I had on my old Gordak station but seems to be softer material. The way it’s designed with the tool standing vertically in the stand makes the air hose forms this loop which depending on your bench setup might or might not bother you but it’s something to consider. But I like the quality of the stand, it’s heavy and feels very sturdy, you get this accessory here which allows you to remove the nozzles while hot and the station has a sensor to detect when the handle is in the stand.

Adjustment of temperature and air level is made through this touch screen control. I’m a bit anti touch screen control on test gear so I would’ve preferred some switches on the front panel but don’t get me wrong, the touch screen works well on this unit, it has nice big touch keys and after setting up your presets you are likely not going to need to adjust the temperature you will just be using the presets like leaded, lead free and another one for heatshrink maybe.

Is this cheaper station a good alternative to the Quick 861DW? This video review should provide you with enough info to decide which one to buy.

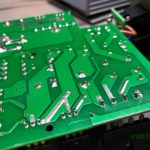

Here are some high resolution images from the teardown:

Voltlog #255 – Gophert NPS-1601 Review (possibly the best power supply in this price range)

Welcome to a new Voltlog, those who have been with me since the beginning of this channel, may know the first video I ever released, Voltlog #1 was a review of a switch mode bench power supply from Gopher Technology. It was the CPS-3205C and it was a great little unit, it has served me well over the years and I still have it.

At that time I complained about the fact that the unit has the output jacks on the back which is not really convenient for bench use. There were also other issues mentioned while measuring the performance of the power supply, I will link that video on screen if you want to watch it but the video, audio and editing quality are lower than what you’re seeing today.

Gophert made some improvements to the original design and have now released a newer version of that power supply, it has a new model number it’s NPS-1601 but it’s the same range of 0-32V and 0-5A. There are other models with different ranges but this is what would correspond to the CPS3205 I reviewed years ago.

They have made a bunch of changes on the front panel, the most important one is they moved the output jacks to the front panel so now it’s easier to connect the output of this power supply but they are still not standard spacing so you can’t connect one of these adapters with banana jacks. They have also redesigned the front panel completely, they are still using 7 segment displays but now they also have a wattage display which can be switched on temporarily in place of the amps display, you press the watts button and it will show watts measurement for about 3 seconds before reverting to amps display.

The switch for A/V adjustment is now tactile instead of a sliding switch but the rest has stayed the same. I like this redesigned front panel I just wished they used a lighter color for the text, because for example there are some markings which are barely visible next to the LEDs.

Here is a set of pictures I captured during the teardown:

Voltlog #254 – Epaper Display Pixel vs Segment Type

Welcome to a new voltlog, today we’ll have a little chat on epaper displays. You probably saw this post I made to my youtube community page a few days ago, it was about my epaper thermometer which suddenly showed the low battery sign and stopped working. I’ve only had this running for 1 month, when I received it, the battery was not connected so I thought it must have been an old battery or a bad one.

Voltlog #253 – Aneng V01A Multimeter Review & Teardown

Welcome to a new Voltlog, today it’s a multimeter review because we haven’t done one in a while and here I have the Smart Digital Multimeter which sounds like a generic name, no obvious branding on the box but granted it is featuring the multimeter on the box, it’s a color image which is not often seen on these cheap meters. On the back, the meter is shown in full black holster and we get a model number sticker, AN-V01 so this probably indicates the Aneng brand.

We’ve looked at Aneng multimeters in the past in Voltlog #114 and others and I’m gonna say this again, Aneng does not make multimeters, Aneng is just a company that rebrands existing multimeters made by other companies.

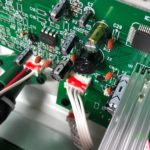

Voltlog #252 – How to fix a solder bridge

Welcome to a new Voltlog, today I want to talk about solder bridges and show you how to deal with them. A solder bridge can happen for many reasons, incorrect soldering temperature, incorrect amount of solder being used, too little or no flux, or just the incorrect technique for soldering but they all basically mean the same thing , a blob of solder shorting two or more conductive surfaces on your PCB.

Modern printed circuit boards which typically get soldermask coverage even between IC pins will help prevent this problem because molten solder normally doesn’t stick to the soldermask surface and so it’s harder to form a bridge across that surface.

But even with enough experience and the proper technique solder bridges can still happen if you do hand soldering on fine pitch ICs, it’s just part of the soldering job. It’s true that as you get better at soldering they will happen less often but don’t think they go away forever. So it’s good to know how to deal with them.