Soldering is probably the thing I do most often at the workbench and so it’s important for me to have a good soldering station. While a JBC station would be the perfect candidate they are super expensive and so out of reach for most hobbyists, that’s why I had to look for something else.

Hakko makes decent soldering stations, especially with their newer T12 cartridge style tips. But you can save even more by choosing an after-market T12 compatible STM32 based soldering station and buying just a genuine Hakko T12 tip from an authorized distributor. So here are references to the tools and supplies I use for soldering.

I use an STM32, Hakko t12 compatible, soldering station which I got a long time ago from Taobao. If you would like to see more details about this station you should watch Voltlog #85. Currently there are similar options available on Aliexpress or Ebay. Things to lookout or ask the seller about: does it have a soft and heat resistant silicone cable? Does it come with a stand, so you can rest the soldering iron? I would advise to get a couple of genuine hakko T12 tips from a known distributor.

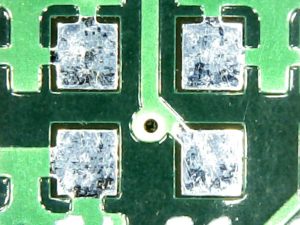

If you get a hakko T12 compatible soldering station you will also need some T12 tips. As mentioned earlier don’t get them cheap from ebay, those are counterfeit tips that do not have the same performance as a genuine tip and this will directly affect how easy it is to solder something. I will list 3 of my favorite tip styles, but depending on the jobs you do these may or may not be the best choice: I use the T12-KU tip daily for almost anything, I use the T12-JL02 for fine smd work and I use the T12-D16 for thicker smd pads.

I sometimes use the hot air station, it’s either for repairs or quick assembly of surface mount components, and sometimes just for heating up heat shrink tubing. I have a very old one called Gordak 952 which is probably a clone of something from Hakko. It must be at least 10 years old but it still works and since I don’t use it everyday I never felt the need to replace it with something newer.

Currently there are better options on the market so take a look at these links on ebay and aliexpress for reference. If you will be using this a lot maybe you want something better, I’ve heard the Quick 861DW is a good hot air station: ebay and aliexpress links.

If you want a great portable soldering iron, I highly recommend the TS100. It was featured in voltlog #186 and I was pleasantly impressed with the performance. It had one downside, that is I couldn’t calibrate the temperature measurement perfectly but I can live with that as long as the performance is good. You can get it from banggood, ebay or aliexpress. I would recommend getting it from banggood because there are also fakes being sold on ebay and aliexpress.

If you are on a tight budget and cannot afford getting the TS100, then you can get an even cheaper portable soldering iron which is powered with a 5V usb port. I’ve used this one successfully before I got the TS100 and powered from a good powerbank I had no problem soldering 18AWG wires. Check it out on ebay, aliexpress.

If you do repair jobs on through-hole components often than you will need a desoldering gun which is practically a soldering iron combined with a pump that can suck the solder away. This is extremely useful if you do a lot of desoldering, the job gets done in a matter of seconds and with stress to the pcb and component. I have the S-993A 90W desoldering gun which was featured in voltlog #101. You can find it on banggood, ebay and aliexpress.

If you rarely do repair jobs on through hole components, than a manual desoldering pump is cheap and might work just fine for you. There are many models available and if you can afford get a good one from a known distributor, they will last longer, if not you can get a cheap one from ebay or aliexpress.

You will also need some supplies for soldering and depending on your location and budget you might find some of these brands while others are unavailable but one thing is for sure: genuine good brand solder wire and flux work so much better than cheap fake stuff.

If we are talking about solder wire, I highly recommend you get the good stuff, because it will have a fine tuned alloy that will melt and flow better while at the same time containing a flux core that will help with soldering. For hobby go with leaded solder wire, here are some good brands to search for: Kester, Multicomp, Alpha, Weller, Amtech, Loctite.

If we are talking about flux, once again I highly recommend you get the good stuff, because it will help with your soldering or repair job while at the same time leave a minimum amount of residue which can be cleaned if necessary. The fake Amtech flux that everybody buys from ebay/china works too, not as good but works. The big disadvantage is that we don’t know what they put inside that flux and we are inhaling those fumes. Also the residue it leaves on a board its pretty hard to clean when compared to the genuine stuff. As a general rule, amtech flux is made in the USA so you can’t get it for a couple of dollars from China. Get it from a known distributor: in Europe try TME, in the US try Louis Rossmann. I recommend the Amtech gel flux NC-559-V2 or ASM variant as well as various flux pens from Kester that can be used for quick jobs.

If you use flux you will be left with some residue on the board after soldering. Most flux types are no-clean type, meaning you can leave the residue on the board and it won’t affect it, however it’s nice to have clean boards so I recommend you get yourself some flux cleaner or IPA (isopropyl alcohol). I find that special flux cleaner works better than IPA in most cases. Any flux cleaner will work here and you will have to find a brand that is available in your area. I am using AG TermoPasty KontaktU because it’s available in Europe from TME. And while you are shopping for flux cleaner also add a can of contact cleaner for that odd electrical job where you need to clean the contacts on some sensor or switch.

Another chemical that is often overlooked is a soldering tip refreshing paste. This stuff will get the shine back on your soldering iron tip, making it ideal for taking solder. During extended usage, because of the high heat and the corrosive action of the flux used for soldering, the soldering iron tip might become oxidized.

So you put the tip inside the refreshing paste and it will clean it. This shouldn’t be used constantly, but only when needed because the past is moderately aggressive so it might wear out your tip prematurely. I use the Mechanic MCN-8S which is a Chinese brand which I find works well and it’s fairly inexpensive. You can find it on ebay and aliexpress.

My preferred method for cleaning the soldering tip is brass sponge. I don’t like the wet sponge method because it applies a thermal shock to the tip, lowering the temperature. The brass sponge is more abrasive and will wear out the soldering tip faster if you overuse it but I just find it works better for me. You can find these on ebay and aliexpress.

Some people use them, some people don’t. I have a magnifier & helping hand combo that even has some LED lights but I only use it once or twice a year. I don’t need magnification when soldering and if I would need magnification I would get a fancy microscope for soldering. Here is the one I have: banggood and aliexpress.

I use a cheap ESD mat and I also have a smaller silicone mat for soldering jobs because the ESD mat I have does not offer protection for higher temperatures while the smaller silicone mat will hapily take the soldering iron or some hot air without melting. There are newer fancy silicone mats that even have different compartments for storing screws, here are some links here: banggood, aliexpress.

As for the ESD mat you might find a local supplier that sells good quality ESD mats or you can order one like I did from aliexpress.

Tweezers are important, they help you handle small smd parts or wires, while soldering them but they can also be useful for other tasks. If you can afford it, get a good quality set, they will last longer and provide a better experience while using them. Good tweezers like the ones from Knipex tend to cost about $15 a piece so instead I’m using cheap tweezers that I usually get from banggood or aliexpress but I do plan on getting one or two of the good ones.

I use a cheap hobby knife (ebay or aliexpress) and cheap replacement blades (ebay or aliexpress). Sure the handle is not great and the blades don’t last very long but they are so cheap that it feels okay replacing them whenever I need a fresh blade.

And that’s pretty much all I use on the bench, if you have any questions, leave a comment below.